SPEEDFAM Free Abrasive Machines are versatile precision machines designed to produce Lapping / Polishing flat surface in the high degree of flatness and surface finish with absolute uniformity on all types of hard & soft materials.

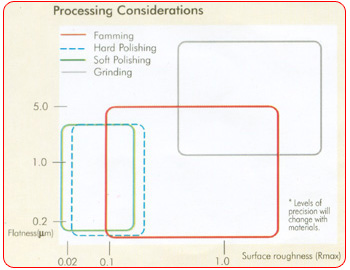

FAMMING

It is highly efficient technique, in which abrasive particles flow freely across the surface of a lapping plate without getting impregnated in the plate. This removes the material from component surface more efficiently, which result in producing flatness on the components.

Applications

| Metals | |

| Valve bodies | Water Pump Seals |

| Automobiles parts | Chemicals seals |

| Valve wedges | Facets |

| Seat rings | |

| Tools & die parts | Semiconductors |

| Mechanical seals | Si wafers |

| Sewing machine parts | GaAs wafers |

| GGG | |

| Watch Parts | |

| Watch dials | Electrical & Electronics |

| Movements & hands | Ferrite Cores |

| Sapphire glass | 'E', 'U' cores |

| Switchgears contacts | |

| Carbon | Rectifiers & Diodes |

| Carbon seals | |

| Submersible pump bearings |

SALIENT FEATURES

- Speed Alloy Segmented Lap Plate Hardness 58 to 62 HRC for faster material removal.

- Water Cooling Jacket for plate to dissipate heat, generated during the process.

- Pneumatic Pressure System for setting accurate & desired load on parts.

- In-Process Lap Plate Conditioning Facility either by Manual or Motorised System.

- Abrasive Re-Circulation System.